How to Identify Trending Cabinet Colors in Your Local Market

Find the trending cabinet colors in your local market by exploring design platforms, paint brands, and showroom trends.

For multi-family builders, choosing the right cabinet color is more than an aesthetic decision—it’s a strategic one. The color palette you select can influence buyer perception, rental appeal, and overall market success. But how can you accurately identify what colors are trending in your local market? Here’s a practical guide that combines digital research, color data, and manufacturing precision.

1. Start with Trend Sources Like Sherwin-Williams and Pinterest

Discover cabinet color trends using sources like Sherwin-Williams and Pinterest for local market inspiration.

A great place to begin your color research is the Sherwin-Williams website, where you can explore the company’s annual color trend reports. These collections are curated by professional designers who track emerging styles and lifestyle shifts.

You can also search on Pinterest, where interior designers and trend forecasters share mood boards featuring the most popular cabinet finishes and color tones. Searching phrases like “2025 kitchen cabinet color trends” or “multi-family design palettes” can give you a clear picture of what’s resonating with homeowners and tenants.

2. Study Local Market Preferences

Color preferences vary by region. To understand what appeals to your target buyers or renters, study the best-selling cabinet colors from established local importers or retailers:

Fabuwood – Known for offering data on their top-performing finishes.

The Home Depot – Browse in-store or online to see the color families dominating their kitchen cabinet section.

These insights help you align your color selections with proven market demand.

3. Document Accurate Color Data

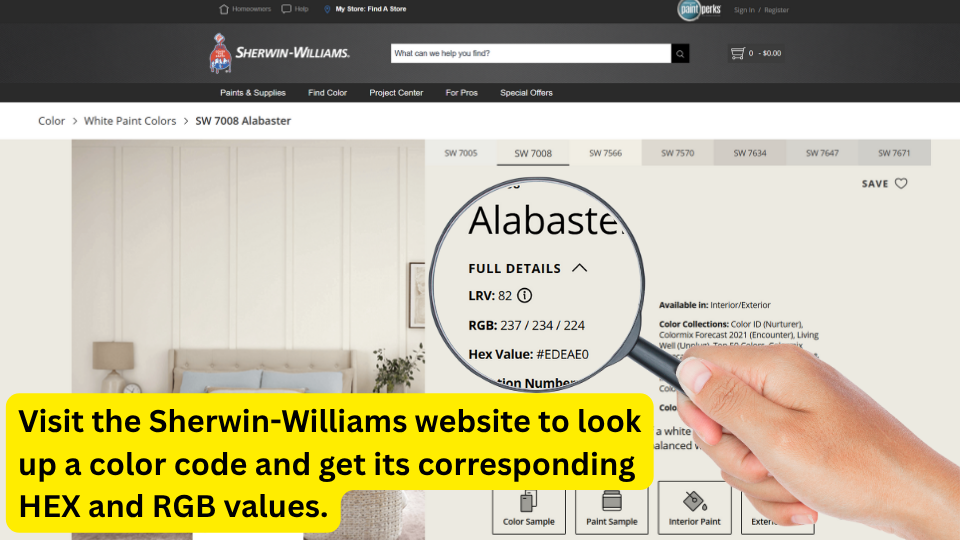

Visit the Sherwin-Williams website to find color codes and convert them to HEX and RGB values for accurate color matching.

Once you identify a color, make sure you record its technical specifications. For example, Sherwin-Williams’ Alabaster (SW 7008) includes:

Hex Value: #EDEAE0

RGB: 237 / 234 / 224

This information ensures that you and your manufacturing partner are referencing the same color data.

4. Convert RGB to Lab* for Factory Use

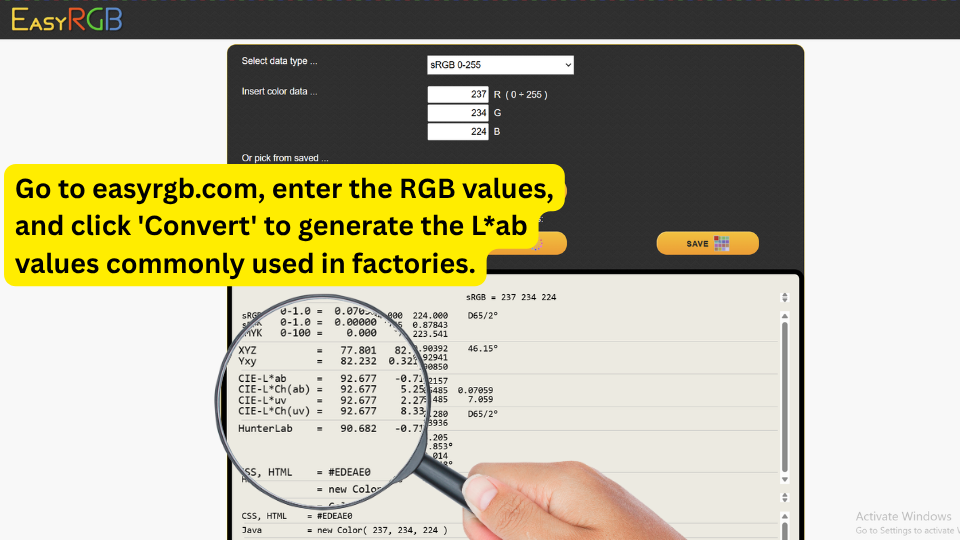

Go to easyrgb.com, input RGB values, and click Convert to obtain L*ab color values used in factory color matching.

Most factories, especially those producing painted cabinets, use X-Rite Ci64 Handheld Spectrophotometers to measure color accuracy. These devices read colors based on Lab* values—not RGB or Hex codes.

Use the X-Rite Ci64 handheld spectrophotometer to measure and ensure precise color accuracy in cabinet manufacturing.

To bridge this gap, you can use EasyRGB.com to convert your chosen color’s RGB data into Lab* values. Sharing the correct Lab* values with your factory enables precise color matching to Sherwin-Williams’ original tones.

5. Matching Colors Without Codes

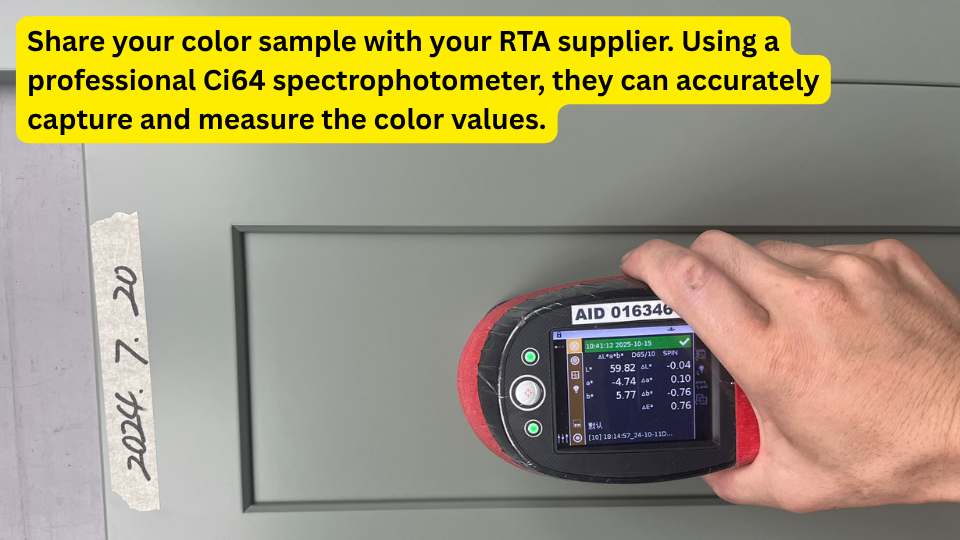

Share your color sample with your RTA supplier. The Ci64 spectrophotometer ensures precise color measurement and matching.

Sometimes you may only have a physical color swatch from a competitor without any RGB, Hex, or Lab* details. In that case, send a portion of the swatch to your factory in Vietnam. Using the Ci64 spectrophotometer, the factory can scan and reproduce the exact color tone—down to the smallest variation.

6. Store Samples Properly to Prevent Color Shift

Store color swatches in sealed, UV-protected containers at a stable room temperature to maintain color accuracy over time.

Painted samples naturally react to air and light over time, which can lead to color drift. To maintain accuracy, store your color swatches in sealed, UV-protected containers at stable room temperature. This ensures that your sample remains consistent for long-term production reference.

Final Thoughts

Strong color management practices are the foundation of successful cabinet manufacturing. By combining trend research, accurate data conversion, and professional measurement tools, multi-family builders can ensure consistent, market-ready color selections that resonate with local buyers.

Stay tuned to ICC’s blog for more professional insights on color management, factory collaboration, and product development strategies for the kitchen cabinet industry.