What Is S4S Timber and Why It Matters for Cabinet Door Manufacturing

When sourcing solid wood for cabinet production, the term S4S Timber often appears on material specifications. But what exactly does it mean—and why is it more expensive than regular lumber? Let’s break down what S4S timber is, how it’s made, and why it plays a critical role in ensuring the stability and beauty of cabinet doors.

S4S timber explained – smooth four sides lumber for furniture and construction use

What Is S4S Timber?

S4S stands for “Surfaced on Four Sides.” This means the timber has been planed, jointed, and cut on all four faces—top, bottom, and both sides—resulting in smooth, square, and dimensionally accurate boards. Compared to rough-sawn lumber, which comes straight from the sawmill, S4S timber is ready for immediate use in furniture or cabinet manufacturing.

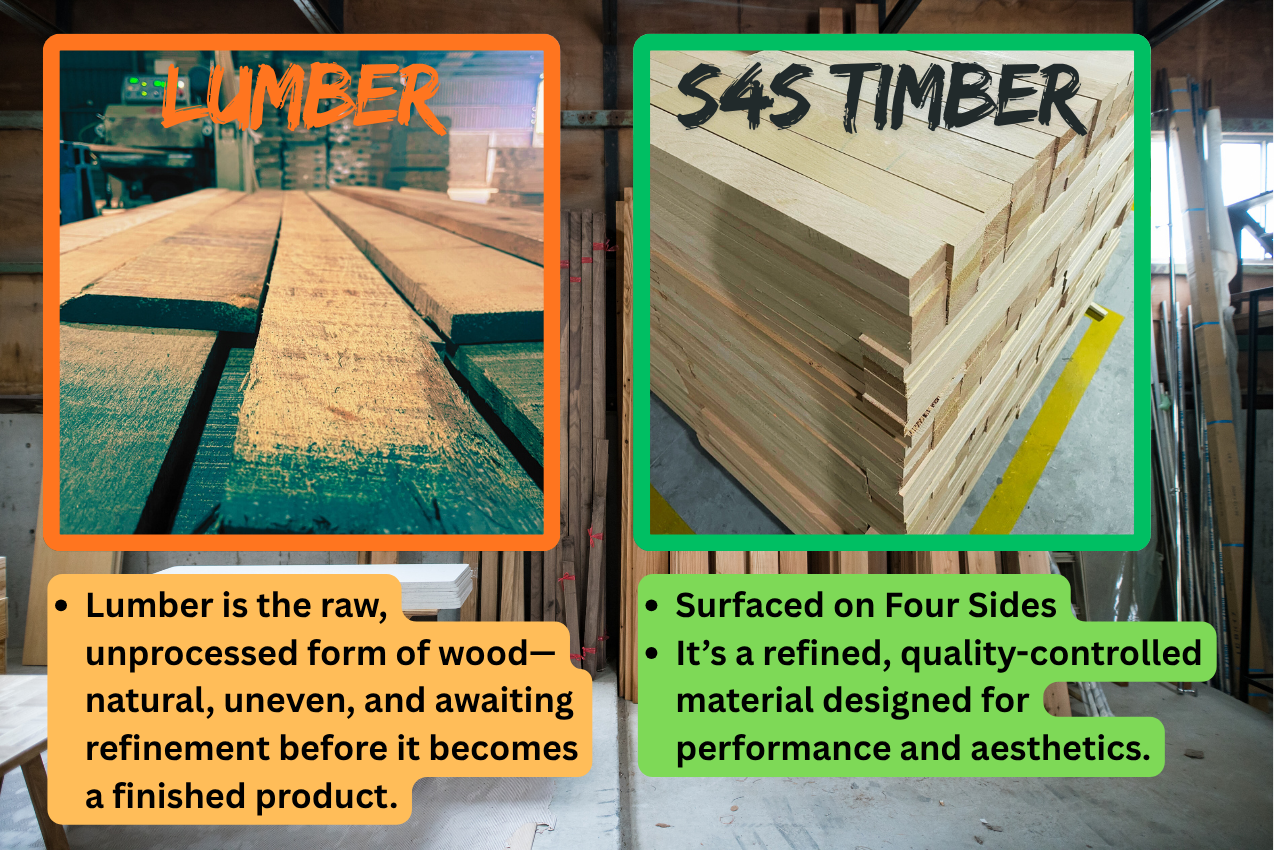

lumber-vs-s4s-timber-difference

The Difference Between Lumber and S4S Timber

The key difference lies in processing and precision. Rough lumber typically has uneven surfaces, inconsistent widths, and higher moisture content. Before it can be used, it must be planed, trimmed, and calibrated—a process that removes defects and ensures consistent thickness.

S4S timber, on the other hand, has already gone through this transformation. It’s straight, smooth, and dimensionally consistent, saving manufacturers valuable time in secondary processing.

The Yield Rate: From Lumber to S4S

Turning raw lumber into S4S timber is not a zero-loss process. During planing, trimming, width calibration, and length cutting, a significant amount of material is removed to achieve a clean and precise finish.

Typically, the yield rate—the usable portion of lumber after processing—ranges from 40% to 50%, depending on the customer’s specifications. If the product requires natural color sorting, the usable yield can drop even further. Boards with color variation are rejected as defective, sometimes reducing the yield to below 40%.

This is why S4S timber tends to cost more than rough lumber: much of the original wood volume is lost during processing to achieve perfect uniformity and color consistency.

Why S4S Timber Is More Expensive?

s4s-timber-material-loss-and-yield.

Several factors contribute to the higher cost of S4S materials:

Material waste: Up to 55% of raw lumber may be lost during surfacing and trimming.

Machining and labor: Precision milling, moisture control, and quality inspection add processing time and cost.

Quality control: When natural color selection is required, additional sorting further reduces usable material.

Dimensional tolerance: Each board must meet strict standards for thickness, flatness, and width accuracy.

In short, S4S timber is not just wood—it’s a refined, quality-controlled material designed for performance and aesthetics.

How to Choose High-Quality S4S Timber

s4s-timber-inspection-process

When selecting S4S timber for cabinet doors or furniture, pay attention to the following criteria:

Moisture content control: Ideally between 8–12% to prevent warping or cracking.

Tight tolerance: Ensure thickness, width, and straightness meet consistent standards.

Color uniformity: Especially important for natural finishes.

Stable sourcing: Reliable suppliers can guarantee consistent grading and quality.

S4S Timber and Cabinet Door Applications

In cabinet door production, S4S timber ensures dimensional stability and smooth surface finish—critical factors for frame-and-panel or solid wood designs. Poor-quality lumber can lead to warping, cracking, or joint failure, especially in changing climates.

That’s why Asia Italian Door (AID) manufactures its own S4S timber in-house. By controlling the entire process—from lumber selection and kiln drying to planing and quality grading—AID guarantees:

Precise tolerance control

Strict moisture regulation

Optional custom selection for natural or stained finishes

This vertical integration ensures AID cabinet doors maintain excellent stability and surface quality. Over the years, AID has built a strong reputation among overseas RTA cabinet importers for producing doors with no cracking, warping, or deformation issues.

Conclusion

S4S timber represents the bridge between raw lumber and finished cabinetry. While it requires higher processing costs and careful material management, the result is a stable, precise, and visually appealing product—perfect for high-end cabinet doors.

For manufacturers and buyers seeking reliable quality from the source, Asia Italian Door’s in-house S4S timber production provides the peace of mind that every board is crafted to the highest standards.